What would you do if you had the chance to save $2M per year with no capital expense and a payback period measured in weeks? Nothing? Have you ever noticed how much time we all spend considering the costs of taking action and how little time we spend considering the

Eliminating Spare Parts Stock Outs

One of the main fears of most reliability and maintenance engineers is that, at the time of actual need, the required spare part will not be available. This is commonly referred to as a stock out. Thus the goal of many reliability and maintenance engineers is to eliminate spare parts

18 Tips for a More Efficient and Effective Stock Take

A stock take can be an administrative nightmare or they can be efficient and effective. It all depends on how they are set up and organized. For access to this post, and all of our content, join using the button below. If you are already registered then

Some Cold, Hard Facts About Stock Takes

One of the key functions that must be carried out with all inventory management is a periodic reconciliation between actual stock holdings and the holdings according to the accounting system. For complimentary access to this article and our entire blog archive, register using the button below. We

More Truth About Inventory Management Theory

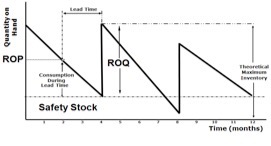

In a previous post we demonstrated that the classic ‘saw tooth’ diagram associated with inventory management and control is sometimes not at all representative of reality for engineering materials and spare parts. In this post, I am going to expand on this to show just how much it can cost

The Truth About Inventory Management Theory

Subject Area: Spare Parts Inventory Management Theory

The Spare Parts Storeroom – More Than Just Transactions

Many people view the spare parts storeroom as being a purely transactional environment. That the function of the storeroom is to administer the transactions associated with receiving and issuing materials and spare parts. But if we really want the spare parts to be maintained so that they will perform as

The Stock Out Metric

The stock out metric is one of the most popular ways to monitor spare parts inventory. A ‘stock out’ occurs when there is demand for an inventory item but there is no stock available. The Stock Out metric is a curious measure and as with all metrics one needs to

Managing Slow Moving Inventory

Is Slow Moving Inventory Really An Easy Target for Inventory Reduction? Inventory that is slow moving is often seen as an easy target for people undertaking an inventory review. Rather than undertake a structured review process (such as the Inventory Cash Release Process) many people will target slow moving

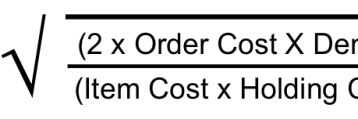

Inventory Management Formula – Knowing is the Easy Part!

In Fact, Just Knowing Inventory Management Formulas is Not Enough Does it really matter if you do or do not understand all the inventory management formula? Does it matter if you know or don’t know how to calculate the Reorder Point or the Reorder Quantity for individual SKUs? Yes,