Each section of our Spare Parts Management Resources Library – we call it the Know-How Center – includes a selection of videos, white papers, articles, podcasts, and presentations relating to that subject area.

Each section of our Spare Parts Management Resources Library – we call it the Know-How Center – includes a selection of videos, white papers, articles, podcasts, and presentations relating to that subject area.

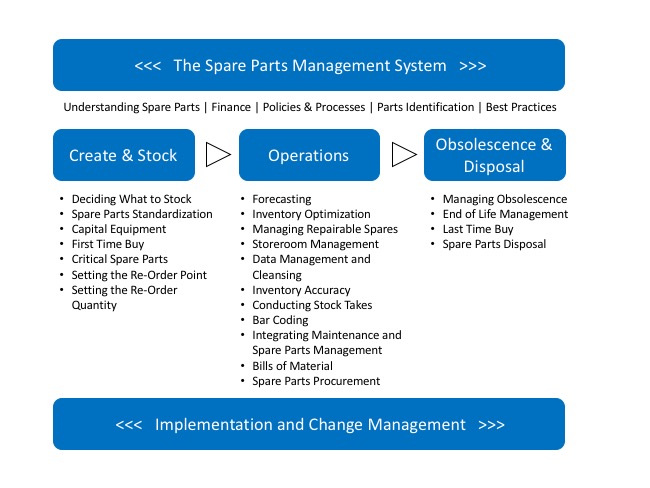

To make it easy to navigate, the Know-How Center is segmented according to the spare parts management life cycle, as shown in the diagram below.

Please note: Access to our Spare Parts Management Resources Library is restricted to Pro Level members.

This section of the spare parts management resources library provides access to resources to help guide the activity and decision making throughout the life cycle of the spare parts held in inventory.

Go to the Spare Parts Management System section >>>

Key topic ares include:

- Understanding Spare Parts Management

- Financial Considerations

- Metrics and Reporting

- Policies and Procedures

- Parts Identification

- Best Practices

This section of the spare parts management resources library starts with addressing the two most important decisions in spare parts inventory management: whether or not to stock an item, and how many to stock.

Go to the Create and Stock section >>>

Key topic areas include:

- Deciding What to Stock

- Spare Parts Standardization

- Capital Equipment and First Time Buy

- Identifying and Managing Critical Spares

- Setting the Re-Order Point and Re-Order Quantity

This section of the spare parts management resources library addresses the longest phase of the spare parts life cycle, that is, the operations phase.

Go to the Operations section >>>

Key topic areas include:

- Forecasting

- Inventory Optimization

- Inventory Optimization: The Inventory Cash Release Process

- Inventory Optimization: Reliability Centered Spares

- The Optimization Trap

- Case Studies

- Managing Repairable Spares

- Storeroom Management

- Data Management and Cleansing

- Inventory Accuracy

- Conducting Stock Takes

- Bar Coding

- Integrating Maintenance and Spare Parts Management

- Bills of Material

- Spare Parts Procurement

This section of the spare parts management resources library address the end-of-life issues with spare parts management. No matter how an item was first created or how long it is part of an inventory, it is almost inevitable that at some point it will become obsolete and therefore require removal and disposal.

Go to the Obsolescence and Disposal section >>>

Key topic areas include:

- Managing Obsolescence, End of Life, and Last Time Buy

- Spare Parts Disposal

This section of the spare parts management resources library addresses the change management required to ensure lasting effect to the improvements made to your spare parts inventory management.

Go to the Implementation and Change Management section >>>

Key topic ares include:

- Implementation

- Continuous Improvement

- Change Management

Please note that the quality of our content is checked and regulated by Phillip Slater, the Founder of SparePartsKnowHow.com