In Fact, Just Knowing Inventory Management Formulas is Not Enough

Does it really matter if you do or do not understand all the inventory management formula? Does it matter if you know or don’t know how to calculate the Reorder Point or the Reorder Quantity for individual SKUs?

Yes, it does.

How many people do you know that don’t bother to learn these inventory management formula when they use software to manage inventory? Or they don’t even seek to understand what algorithm the software applies for the calculations? Surely knowing these things is the starting point for anyone charged with inventory management.

What if you do know the inventory management formula, is that enough to make you an expert manager?

Many people seem to think so but is it really enough to enable you to improve your materials and inventory management results?

In my opinion it is not.

What You Need to Understand is the Implications of Applying the Inventory Management Formula

Certainly, it is worthwhile understanding the basic inventory management formula and elements of materials and inventory management but, as in many situations, the real value comes from looking beyond the basics and understanding the implications of the choices that are made regarding the variables used in any formula.

Anyone can look up inventory management formula on the Internet or read them in any number of books on the subject (and I encourage those that don’t know the basics to do so) but it is an understanding of the nuances in the variables that provides the real value.

Too often people take the basic concepts and inventory management formula and do not think through the complicating factors when implementing the concept or formula. This does not mean that we need to make things overly complex; it just means that we need to understand the implications of our choices.

My criticism of people in industry is that they can somewhat blindly apply inventory management formula without thinking about the implications of their choices in the variables that are used. They tend to think that knowing a formula is the smart bit but, in my view, that is the easy part. The smart part is to understand and manage the implications of the choices that are made.

The ROQ (or EOQ) Formula

For example, in the ROQ calculation, I think that one of the most contentious values is the cost of placing/processing the order and this needs to be better understood as the calculation is quite sensitive to variations in this number. Here is an example.

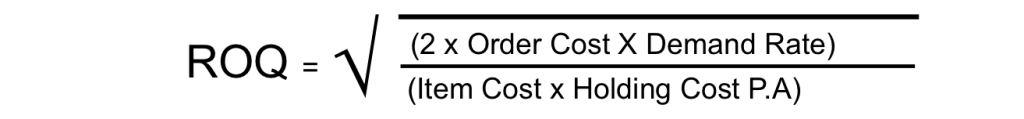

The classic formula for calculating the ‘economic’ ROQ is as follows:

ROQ = SQRT((2 x Order Cost x Demand Rate)/(Item Cost x Holding Cost p.a.))

Where:

SQRT = Square Root

Order Cost = the company internal cost for processing requisitions, issuing purchase orders and receiving deliveries.

Demand Rate = the expected demand over a year.

Item Cost = the purchase cost of the item, including delivery costs.

Holding Cost p.a.= the financial charge for holding inventory

Now, let’s assume that:

Order Cost = $50 per order

Demand = 1,000 per year

Item Cost = $10 each

Holding Cost = 25% per year

Then

ROQ = SQRT((2 x 50 x 1,000)/(10 x 0.25))

= 200

Therefore, the ‘economic’ ROQ is 200 items.

Now, let’s look at the impact of changing the Order Cost. Assume that we change the Order Cost to $100 and all other variables remain the same, then

ROQ = 283

So, if an order cost of $100 per order is used the ‘economic’ ROQ will be calculated to be 283 items – approximately 41% higher than if an order cost of $50 is used. This simple change in a variable has increased the reorder value of this item by 41%!

Understand the Impact of Your Choices

Imagine the effect on your total inventory value if you do not understand the impact of the choices you make with these and other variables. Just knowing the inventory management formulae is the easy part!

For information on our Pro Level membership please visit our Pro Level page.

Posted by: Phillip Slater