This article covers:

- The definitions of Min, Max, ROP, and ROQ

- Why the differences are meaningful and important

- The pros and cons of using each

- Why you need to get this right

- Links to further reading

There are essentially two ways that companies express their inventory control settings: either as MAX- MIN (sometimes MIN-MAX) or ROP-ROQ.

Some people will say that it doesn’t really matter which you use, just as long as you understand the definitions and the pros and cons. However, in my experience it does matter and this is one aspect of spare parts inventory management that you really do need to get right.

Definitions for MIN, MAX, ROP & ROQ

MIN = short for minimum.

MIN = short for minimum.

There is, confusingly, two schools of thought about what is meant by the MIN. Most typically this is the point at which the need to order more stock is triggered. Sometimes, however, the MIN is seen as the minimum quantity that can be safely held to cover expected needs. In this case the need to order more stock is set so that the reorder point is one less than the MIN value. That is. MIN -1.

The key to managing when using a MIN setting is to understand the configuration of the computer system you use, as different definitions will change the resulting holding level, the re-order point, and perhaps even the actual safety or buffer stock.

MAX = short for maximum.

This value is most typically the targeted maximum holdings of the item. Usually, in a MAX- MIN system, where the MIN is the reorder point, the quantity reordered after reaching the MIN is the quantity required to get back to the MAX. For example, if the MAX- MIN is 5-2, when the quantity in the storeroom reaches 2, procurement would need to order 3 to get back to the MAX.

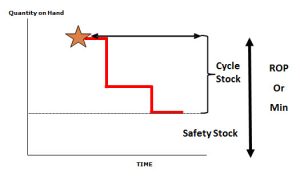

ROP = Reorder Point

As the name suggests, quite simply, this is the stock level at which the need to reorder is triggered. This is calculated by determining the safety stock level and the stock required to service needs during the reorder lead time.

ROQ = Reorder Quantity.

Again, as the name suggest, this is the quantity to be reordered when the ROP is reached. This is not the EOQ but rather the quantity that both makes economic sense and is commercially available.

The Differences are Meaningful and Important

It is essential that every inventory manager understands that the MAX- MIN and ROP-ROQ approaches are not simply interchangeable.

For example, in general terms:

MIN can be equated with the ROP, except if you have a system set up for reordering at a point of MIN-1. In that case, there is no equivalence.

For slow moving items the MAX can in some circumstances be equal to the ROP + ROQ. This is because for slow moving items it is possible that there will be no additional demand before the newly ordered item(s) arrive in stock.

However, with all other items the MAX is UNLIKELY to be equal to the ROP + ROQ as items may be issued between the time of reaching the MIN and the newly ordered items arriving. In fact, there is a logic that says that the MAX would never actually be achieved.

Do these differences matter? I think that they do.

For example, what if you change IT systems? If you move from one type of MAX-MIN system to another but they define the MIN differently then you cannot just migrate your data. This may not seem obvious if everyone is using the language of MAX-MIN but is classic trap where words are used in different ways.

Similarly, if you are benchmarking your holding levels with another company or site then you need to be aware of the different definitions and the outcomes that each approach would achieve. Otherwise you are comparing ‘apples with pears’.

Or what about what happens when a new team members arrives at your company and their previous company used the terms MAX-MIN but with different parameters or meaning to that your company uses. There will likely be an assumption that the terms are used in the same way and this could lead to stock shortages or overstocks, depending on the differences in the definitions.

To add further confusion, some software systems use the term ‘Safety Stock’ to represent the MIN holding level, despite this not being the universal definition of safety stock. This different nomenclature leads some people to assume that holding less than the so-called ‘safety stock’ according to your IT system is ‘unsafe’ or risky, when in fact it may not be at all. They may even be holding an excessive level of stock because they don’t properly apply the term ‘safety stock’. Calling it safety stock does not make it so.

Pros and Cons

MAX-MIN

Pros:

• Conceptually simple to understand.

Cons:

• Terms can be misleading in terms of safety stock and actual maximums.

• Terms are used in different ways and so caution required to ensure a common understanding.

• Values often set using ‘experience’ or intuition.

• Often leads to overstocking while reporting misleading overstock data

ROP-ROQ

Pros:

• Meaning of each term is clear and consistent.

• Values set using auditable logic.

• Safety stock values clearly established.

• Holdings more likely to reflect the actual needs and commercial constraints.

Cons:

• Requires more work to determine the appropriate values.

Why You Need to Get This Right

The differences between MAX-MIN and ROP-ROQ are not trivial and the terms certainly are not interchangeable. In my experience, the ROP-ROQ approach produces greater transparency and is easier to manage because there is no confusion about the meaning of the terms. This approach also produces a more appropriate and auditable level of inventory.

This suggests that if spare parts inventory management is important to you then you really do need to get this right.

Pro Level members at SparePartsKnowHow.com can access an extended paper titled, A Practical Method for Determining Spare Parts Holding Levels. As the name suggests this paper details a simple and transparent method for determining the ROP and ROQ and shows you how to do this in three easy steps.

Click here to download a copy.

For information on our spare parts management online training please visit our Pro Level page.

You might also be interested in these articles and videos:

How Your SAP Safety Stock Definition Can Drive You to Overstock Your Inventory.

Two Types of Inventory Accuracy

8 Reasons Why Spare Parts Management Is Different

Managing Slow Moving Inventory

Two reason Improved Maintenance Won’t Save Your MRO Spare Parts Problems

Author: Phillip Slater