Stock turn is one of, if not the, most important metrics that you can use to measure the effectiveness of your spare parts inventory management. However, like all metrics you do need to calculate it and use it in the right way. One of the most common issues with stock

A New, Simple ReOrder Point Calculator

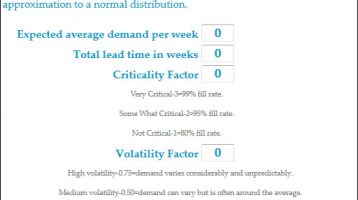

One question that people ask me regularly is: how do we access a simple reorder point calculator for the ROP for spare parts when our data is inadequate or unreliable? Well, now we have a way to do just that! At SparePartsKnowHow.com we have created a reorder point online calculator

The Spare Parts Repair or Replace Decision

Recently I needed to make a spare parts repair or replace decision because I experienced something that might be familiar to some readers – an equipment breakdown! Last week I was mowing the lawn at the back of my house when my 15 year old lawn mower just gave up.

Definition of Just In Time (JIT)

Just In Time (JIT) is perhaps the most often quoted, and yet misunderstood, term in management. JIT, developed as one pillar in the Toyota Production System (the other being autonomation), is a production management method that aims to eliminate waste and improve product flow on a production line. This is

5 Common Techniques for Spare Parts Management That You Should NOT Use

In this recording of a public webinar Phillip Slater identifies 5 common techniques for spare parts management that you should not use. Phillip explains what they are and why they should not be used. For information on our Pro Level membership please visit our Pro Level

Why Spare Parts are Different to Other Inventory Types

In October 2012 Phillip Slater was interviewed by Dustin Mattison for the Kinaxis Supply Chain Expert website. In this interview Phillip discusses why spare parts are different to other inventory types and what this means for those that manage spare parts inventory. For information on our

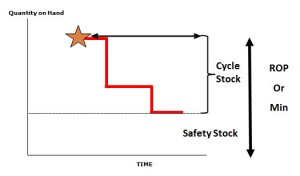

Reorder Point Definition – What You Need to Know

Understanding the Reorder Point Definition is Vital Understanding the reorder point definition is a vital element of understanding and being able to effectively execute spare parts management. With a clear understanding of the reorder point definition companies can avoid two key problems: The problem of overstocking due to over-estimating the reorder

Economic Order Quantity Definition

EOQ is often misunderstood to be the purchase quantity that provides the lowest purchase cost per unit. For example, when buying in bulk, and as a result many organizations overstock their inventory believing that they are doing the right thing. However, a better definition of Economic Order Quantity takes into account

ABC Analysis Definition

An ABC analysis is an analytical approach to inventory management. The analysis aims to divide the inventory items into categories and then tries to identify the items that are most important. Typically A is more important than B and B is more important than C and so on. The

Working with Maintenance to Identify Spare Parts Requirements

Without knowing the maturity of your decision making framework and policy settings I can’t give a specific response to a question so here is the generic version. Working together, you and the maintenance team need to understand the maintenance requirements for the equipment and the spare parts implications of this.