Just In Time (JIT) is perhaps the most often quoted, and yet misunderstood, term in management. JIT, developed as one pillar in the Toyota Production System (the other being autonomation), is a production management method that aims to eliminate waste and improve product flow on a production line. This is usually achieved through the application […]

5 Common Techniques for Spare Parts Management That You Should NOT Use

In this recording of a public webinar Phillip Slater identifies 5 common techniques for spare parts management that you should not use. Phillip explains what they are and why they should not be used. For information on our Pro Level membership please visit our Pro Level page. Posted […]

Why Spare Parts are Different to Other Inventory Types

In October 2012 Phillip Slater was interviewed by Dustin Mattison for the Kinaxis Supply Chain Expert website. In this interview Phillip discusses why spare parts are different to other inventory types and what this means for those that manage spare parts inventory. For information on our Pro Level membership please visit […]

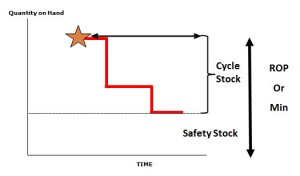

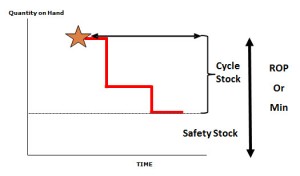

Reorder Point Definition – What You Need to Know

Understanding the Reorder Point Definition is Vital Understanding the reorder point definition is a vital element of understanding and being able to effectively execute spare parts management. With a clear understanding of the reorder point definition companies can avoid two key problems: The problem of overstocking due to over-estimating the reorder point. The problem of stock […]

Economic Order Quantity Definition

EOQ is often misunderstood to be the purchase quantity that provides the lowest purchase cost per unit. For example, when buying in bulk, and as a result many organizations overstock their inventory believing that they are doing the right thing. However, a better definition of Economic Order Quantity takes into account the total cost of holding […]

ABC Analysis Definition

An ABC analysis is an analytical approach to inventory management. The analysis aims to divide the inventory items into categories and then tries to identify the items that are most important. Typically A is more important than B and B is more important than C and so on. The criterion for the division can change […]

Working with Maintenance to Identify Spare Parts Requirements

Without knowing the maturity of your decision making framework and policy settings I can’t give a specific response to a question so here is the generic version. Working together, you and the maintenance team need to understand the maintenance requirements for the equipment and the spare parts implications of this. For example, what is the […]

Safety Stock Definition

Understanding safety stock is one of the most important attributes of high performing spare parts inventory management. Companies that do not understand this will almost invariably over stock their inventory AND experience excessive stock outs. Here is the definition of safety stock. Safety Stock: Items held as an allowance for mismatches between demand and supply […]

Obsolete Inventory: Your Risk is Greater Than You Think

I am sure that you know that risk management is a key aspect of any mature spare parts management process and this is especially so with respect to obsolete inventory. Usually, this takes the form of evaluating the risk associated with a stock out – that is not having a required item available when needed. […]

Excess Inventory: The Real Cost of NOT Reviewing Your Inventory

Excess inventory: What is the real cost of not reviewing your inventory management processes? That’s right I said the cost of NOT reviewing your inventory. Usually when people (me included) raise the topic of the cost of inventory we talk about the financing and management costs of holding inventory. However, with spare parts many people […]