This article discusses spare parts numbering systems and covers:

This article discusses spare parts numbering systems and covers:

- What is a spare parts numbering system?

- Intelligent and dumb spare parts numbering

- Which approach to use

A spare parts numbering system is a way to differentiate items within your spare parts inventory without constantly referring to long descriptions. It is short-cut for spare parts identification.

For example, a bearing may be described as a cylindrical single row roller bearing with internal diameter of 20mm, outer diameter of 47mm, width of 14mm, with a dynamic load rating of 28.5kN and a limiting speed of 24,000 rpm. Phew, that is a mouthful!

Using that description every time the bearing is specified on a work order or as part of a storeroom transaction would be tedious and prone to error. Better to refer to that bearing using a simple in-house part number. This part number then refers to an inventory catalogue that contains all of the technical detail just mentioned.

A company’s spare parts numbering system should be different to vendor or manufacturer numbers because not only do vendors and manufacturers change but they may also change their own parts numbers as products are updated. While the vendor’s number is important for all procurement communications with that vendor, it is better to use your own part numbers and reference the vendor numbers in the data set associated with that part.

Intelligent and ‘Dumb’ Spare Parts Numbering

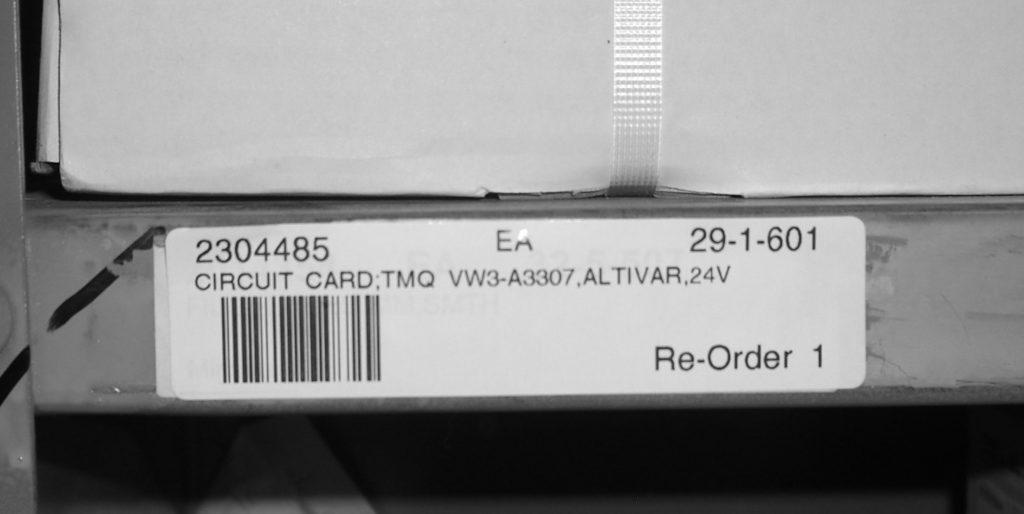

An intelligent parts numbering system is one in which the part number has some meaning beyond being a simple identifier. For example, all bearings may start with the designation ‘BRG’, then there may be a size descriptor such as ‘OD047’ indicating an outside diameter of 47mm, and then a serialized suffix such as 001. Thus, one bearing might be BRG-OD047-001 and another, similar bearing, may be BRG-OD047-002. While the ‘intelligent number’ tells us something about the part it also is used as a reference to the detail that is part of the catalogue system.

The main advantage of using an intelligent parts numbering system is that it can reduce errors because the user can look at the part and determine if it matches the description based on the number. For example, if given a bearing with an outside diameter of 35mm but using the part number BRG-OD047-001 the user can tell that they have the wrong part. The main disadvantage of using an intelligent parts numbering system is the training involved to ensure that everyone understands the meaning in the part numbers.

A ‘dumb’ parts numbering system is one where the part number contains no specific information about the part, it is typically a sequential number allocated purely as a reference to a database.

In this case the bearing above may be part number 123456. The main advantages of a ‘dumb’ system are that it is easy to generate parts numbers as they are usually sequential, and there is no training required to understand the number. The main disadvantages are the potential for errors because the number has no meaning and there is a need to ensure that the descriptive data in the catalogue is sufficient for identification.

Which Approach to Use

There was a time when intelligent part numbering systems were very much in fashion but the advent of modern search engine techniques seems to have largely shifted the balance to the ‘dumb’ approach. This is workable just so long as the supporting description and data is consistent and has meaning to a person rather than just a machine or bar code reader. This requires adherence to a spare parts description naming convention.

You might also be interested in these articles and videos:

Spare Parts Inventory Data Governance and Cleansing.

Two Types of Inventory Accuracy

3 Questions to Ask About Spare Parts Standardization

What is a Spare Parts Numbering System?

How to Improve Your Spare Parts Management Results With High Quality Materials Data

Author: Phillip Slater