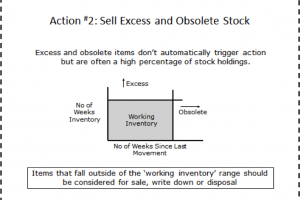

Operationally, excess and obsolete inventory items generate little interest because they do not create emergencies and so few companies pay much attention to this inventory unless or until they undertake a specific program of review. In the normal day-to-day management these inventory items are mostly ignored and the focus tends

Inventory Optimization Actions for Spare Parts

This post is set up as a portal to the series of items relating to the Inventory Cash Release Process. This process is specifically designed to assist companies managing spare parts with inventory optimization and reduction. The Inventory Cash Release (ICR®) Process, is a structured step-by-step inventory optimization technique that

Spare Parts Inventory Reduction: Russell Thompson Tells How SparePartsKnowHow.com Helped Him Achieve a 50% Inventory Reduction

In October 2011 Russell Thompson, Corporate MRO/Purchasing Manager at Idahoan Foods in the USA joined SparePartsKnowHow.com as a Member. In the time since then Mr. Thompson has used the resources at SparePartsKnowHow.com to achieve a 50% spare parts inventory reduction. In this extract from a recent interview he tells

Inventory Reduction Action #1: Have Someone Else Hold and/or Pay For Inventory

The best way to reduce the investment in inventory is to eliminate the investment altogether. This inventory reduction action can be achieved without risk and with full access to the inventory by having someone else hold and/or pay for the inventory. This approach, sometimes known as consignment stocking, transfers both

The Inventory Cash Release® Process – A Step By Step Guide

First – Download the Flowchart — The content below this line is only visible to logged-in members — To help you follow this explanation of the basic framework I have set up a flow chart for you to download. You can do that here: ICRFlowChart. The following

The Inventory Cash Release® Process

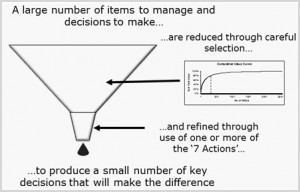

[grwebform url=”https://app.getresponse.com/view_webform_v2.js?u=uY&webforms_id=14719202″ css=”on” center=”off” center_margin=”200″/] Over the years this blog has explored many aspects of spare parts inventory management and usually there is a little feedback on each article. But when I recently mentioned in one article the 7 Actions for Inventory Reduction the response was unprecedented. Apparently many readers hadn’t heard of this approach

Inventory Reduction: Why 30% is Easier to Achieve than 3%

Here is something to think about: it is easier for companies to achieve a 30% inventory reduction than a 3% reduction. I know that this statement is counter-intuitive so you may be saying to yourself: How can that be, surely achieving a lower target is easier than achieving a

Excess Inventory: The Real Cost of NOT Reviewing Your Inventory

Excess inventory: What is the real cost of not reviewing your inventory management processes? That’s right I said the cost of NOT reviewing your inventory. Usually when people (me included) raise the topic of the cost of inventory we talk about the financing and management costs of holding inventory. However,

Rationalizing Inventory With Multiple Locations

Q: One thing I’d be interested in knowing more about is rationalizing inventory. To elaborate, what I’m interested in knowing more about is how companies that have multiple locations in a region are able to take spares that are carried at each location and rationalize (or store at one location)

Why Your Inventory Management Software Gives You The Wrong Answer

Many of my clients get quite frustrated with their inventory management software – especially the type of software that they use to calculate ‘optimal’ holding levels. What they tell me is that they typically and frequently get from their software crazy numbers that just don’t make sense. In fact, it