If the benefits os spare parts inventory optimization are both significant and achievable, what is stopping you from working on it today, right now, even as you get on with your daily tasks?

What do you expect to achieve through a program of spare parts inventory optimization?

Some of the typical answers to this question are:

- Improved availability of the required parts

- Reduced total spare parts investment

- Procurement savings

- Space savings

- Working capital savings

All worthy goals.

So if the benefits are both significant and achievable, what is stopping you from working on your spare parts inventory optimization today, right now, even as you get on with your daily tasks?

This question generates another list of common responses:

- Insufficient resources/time

- Data quality

- Incomplete or lack of Bills Of Materials (BOMs)

- Awaiting software approval from the IT department

These are all important issues but they should not be impediments to conducting a ‘why spare parts inventory optimization’ review.

Yes, it would be great if you had more resources and the luxury of time to do this work but realistically when does that ever really happen?

Sure great data will help identify parts and duplications but in 99%* of cases you will not have a true history of parts usage. Typically you will have an incomplete history of parts movements and that is a very different thing from usage.

Up to date and complete BOMs are great for maintenance but the information needed for spare parts inventory optimization is available without this.

Naturally you want the IT department to put evaluation of your requirements at the top of their list but you actually don’t need any special software to optimize your spare parts inventory.

So let’s be clear: you can conduct your spare part inventory optimization review without any of this, if you choose to apply the right process.

This is because the answers you seek are tied up in a combination of your processes and experience plus a little, easy to access, data.

Stop for a minute and think through the actions required to achieve the benefits listed above.

First you need to identify which items to review. It makes no sense to review all items in your inventory because, frankly, for many items it won’t make any difference either financially or operationally if you hold 2, 3 or 10. These are low cost items that have low or no criticality. Just be taking this one simple step you can reduce the workload for your spare parts inventory review by as much as 90%.

Next, you need to recognize that spare parts inventory optimization is achieved by people using their know how and experience. Therefore you should systematically apply a review methodology that is logical and process based.

The process that I advocate is the Inventory Cash Release Process. This process takes you through a series of seven questions relating to each spare part and its supply and demand attributes. From that you will identify opportunities for optimization based on operational need, vendor relations, internal process, and identification of requirements.

Then you need to record the decisions made and execute the actions.

This approach can be applied to any segment of your inventory. If you want to target a specific group of inventory, say bulky items that take up lots of space, you can do that. If you want to target critical items, you can do that.

It is because the process is straightforward and doesn’t require any specific software that it can be applied as part of your daily work. Of course it works best when applied by a focused team but the framework is applicable to any sparing decision made on a daily basis.

Of course, you will be right to ask if the results compare with software and other approaches.

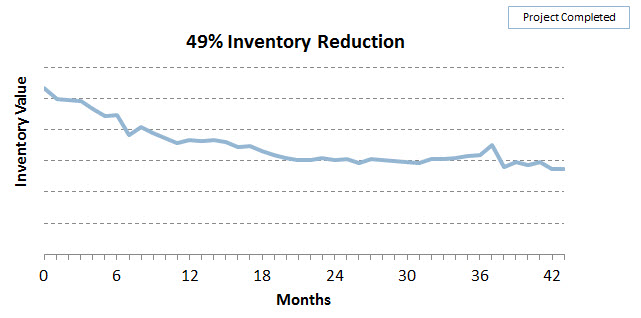

The answer is that in fact the results are better. This is because the approach effectively enables an unconstrained optimization whereas software is highly constrained. On average this approach has historically delivered a 36% inventory reduction but sometimes it can be as high as 50%!

The point here is that once you think through the actual requirements for spare parts inventory optimization you can see that it is simple and easy to go about your review without facing the issues that commonly delay and even prevent action.

Spare parts inventory optimization is not as hard as many people will have you think. It is achievable without specialist software and without a massive commitment of time. And that is why your spare parts inventory optimization program can start today.

*estimate

For more information please visit our Pro Level page.

Author: Phillip Slater