There seems to be a common belief in spare parts inventory optimization that a complete solution can be achieved by tackling just one aspect of the spare parts inventory.

There seems to be a common belief in spare parts inventory optimization that a complete solution can be achieved by tackling just one aspect of the spare parts inventory.

But this isn’t really the case. It takes a range of actions to achieve spare parts inventory optimization.

For example, I hear people all the time saying that they are going to focus on slow moving items or improving maintenance planning or reviewing purchase quantities and so on.

Individually these will all make some difference to your inventory levels but individually they do not represent a complete solution. Or even a thorough examination.

It appears to me that often people hear of some success elsewhere and they think they can just apply that single solution to their inventory.

Or they just know that they don’t want to have slow moving parts and so they target those. (Confusing the impact of slow moving spare parts with other types of slow moving inventory is one of the greatest errors that companies make but I will leave that discussion to another day).

The reality is that a company can not apply what I call a single point solution and actually achieve a comprehensive benefit.

Unfortunately the world of spare parts management does not work like that.

With spare parts management a single point solution is not enough and the reason is that all inventories are different.

Not only are they different in make up but they are managed differently, they have different levels of data quality, they are in different geographic locations, they support different levels of maintenance sophistication.

Some years ago I developed an approach to spare parts optimization that recognizes and addresses these differences. This is called the Inventory Cash Release Process and it applies the 7 Actions for Inventory Reduction.

By applying the 7 Actions, instead of just one action, you get a far better and more rounded solution.

The important point here is that the actions that have the most impact will vary from company to company – not everyone is the same – and you won’t necessarily know in advance which action will have the most impact at your company. Applying single point solutions is like throwing darts in the dark: sure you might hit something but it won’t be as effective or efficient as it could be.

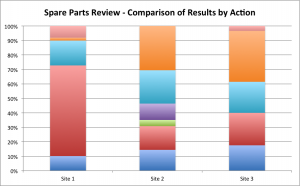

Accompanying this post is a graphic that shows inventory optimization results from three different sites that applied the ‘7 Actions’ approach.

You can see that the impact of each action is different at each site.

They had no way of knowing in advance which action would give them the most benefit but by applying all seven actions they make sure that they don’t miss any genuine opportunity.

The importance of this is amplified when I tell you that the average reduction across these sites was 42%!

As you can see from the graphic, if they had applied just one action to this inventory optimization task they would have missed out on a large chunk of their savings.

For example, improved planning and coordination delivered just 2% savings at one site but 35% at another.

Reviewing excess and obsolete inventory delivered just 17% of savings at Site 2 but a whopping 62% of savings at Site 1.

Even so, if that was all they did at Site 1 they would have missed out on nearly 40% of their total benefit!

Applying a single point solution might seem attractive because it looks simple but don’t be fooled into thinking that it is also effective. The single point solution will more often than not leave you well short of achieving your full spare parts inventory optimization potential.

For more information please visit our Pro Level page.

Author: Phillip Slater