The Acquisition Trap What happens when most companies purchase or develop software for solving their spare parts inventory management problems? Typically, they will spend a lot of time, energy and money trying to integrate their purchase into their existing systems but ultimately, over time, they will make little or no

Why Spare Parts Inventory Optimization Can Start Today

If the benefits os spare parts inventory optimization are both significant and achievable, what is stopping you from working on it today, right now, even as you get on with your daily tasks?

Spare Parts Inventory Optimization Vs. Spare Parts Inventory Prevention

Subject Area: Spare Parts Inventory Prevention Spare parts inventory optimization takes up a lot of time and energy at many companies. But the problem with spare parts inventory optimization is that it happens after you have spent the money! Rather than work on spare parts inventory optimization perhaps a better

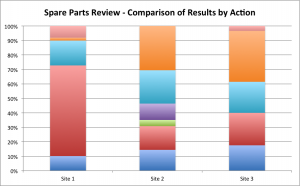

Proof that Single Point Spare Parts Inventory Optimization Leaves You Short

There seems to be a common belief in spare parts inventory optimization that a complete solution can be achieved by tackling just one aspect of the spare parts inventory. But this isn’t really the case. It takes a range of actions to achieve spare parts inventory optimization. For example, I hear

Isn’t It Time That We Started Talking About Inventory Prevention?

If the goal really is spare parts inventory optimization, then surely doing the work after the parts have been purchased is just wrong. Shouldn’t we be taking action before the parts are purchased? Shouldn’t we be talking about inventory prevention? Spare parts inventory optimization is great. It helps companies

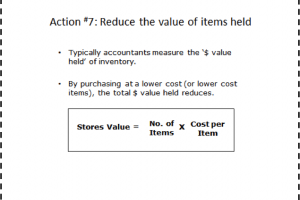

Action #7: Reduce the Value of Spare Parts Items Held

To reduce the value of spare parts items held is the last of the 7 Actions for Inventory Reduction and is probably the most obvious, but perhaps because of that the most overlooked. Most cost reduction actions are aimed at reducing the cost of an item for the obvious profit and

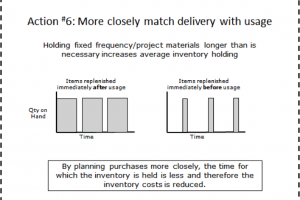

Action #6: Match Spare Parts Delivery With Usage

Each of the actions discussed in this series so far has been looking at ways to reduce the physical number of items held. However, one of the variables that drive the cost of holding inventory is how long you hold the inventory. This represents the amount of time that you

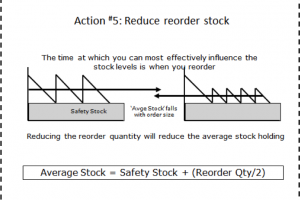

Action #5: Reduce Spare Parts Reorder Quantity

As discussed in other articles in this series, there are essentially two actions that you can take to reduce spare parts inventory: remove existing inventory or reduce the amount of inventory going in. We call this the bathtub principle because it is similar to pulling the plug in a bathtub

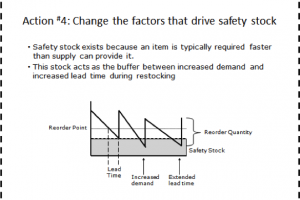

Action #4: Change the Factors that Drive Safety Stock

With inventory reduction there are essentially two actions that you can take: remove existing inventory or reduce the amount of inventory going in. We call this the bathtub principle because it is similar to pulling the plug in a bathtub to let water out or closing the faucet to reduce

Action #3: Eliminate Spare Parts Duplication

The first two actions in the Inventory Cash Release Process (Have Someone Else Hold and/or Pay For Inventory and Sell Excess and Obsolete Stock) both involve taking items out of the inventory and this is also the case with Action #3: Eliminate Duplication. Almost by definition, spare parts duplication adds no