Over the past few months I have been working through a series of five best practices for spare parts management. If you missed any of those items you can catch up via the links below. But there is one thing that you must do if you want to take advantage of applying

The Two Reasons Why You Hold Spare Parts Inventory

In this Two Minute Tutorial Phillip Slater discusses the only two reasons why you (or anyone) holds spare parts inventory. The first reason is when you can’t access supply within your planning horizon. For example, if you have a need for a spare part that is critical to your operations and the

Why Isn’t Procurement Treated as a Partner in Spare Parts Management?

When it comes to the management of spare parts used for maintenance and operations support, the procurement team is often treated as an outsider, a service provider, rather than a partner in ensuring that the objective of maintaining operational capacity is achieved. In my experience, this approach is a drag

Spare Parts Management Best Practice #5: Eliminate Squirrel Stores

For access to this post, and all of our content, join using the button below. If you are already registered then you need to log-in. Those of you who have been reading my blog posts for some time will know

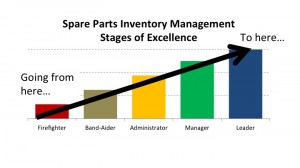

Stop Being Incremental with Spare Parts Management

There is an old management maxim that says that ‘the good is the enemy of the great’. The way that I interpret this expression is that make real progress with their spare parts inventory management companies need to stop being incremental. This is because incremental activity makes us feel like

Spare Parts Management Best Practice #4: Develop Clear ROP & ROQ Logic and Guidelines

For access to this post, and all of our content, join using the button below. If you are already registered then you need to log-in. Spare Parts Managment Best Practice #3 required that you develop your stock/don’t stock criteria

Spare Parts Management Best Practice #3: Define Your Stock/Don’t Stock Criteria

For access to this post, and all of our content, join using the button below. If you are already registered then you need to log-in. We have all been there: you are deciding whether or not to stock a

Spare Parts Management Best Practice #2: Regular Reviews

For access to this post, and all of our content, join using the button below. If you are already registered then you need to log-in. One of the major problems with spare parts management is the attitude of ‘set

Spare Parts Management Best Practice #1: Create Transparency

For access to this post, and all of our content, join using the button below. If you are already registered then you need to log-in. In short, this best practice requires that you create transparency in your spare parts

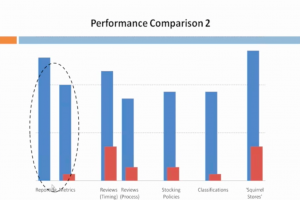

Defining Best Practice for Spare Parts Management

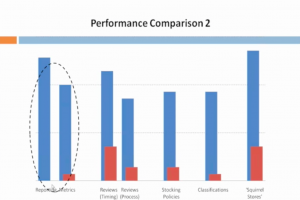

Defining best practice for spare parts management can be tough. In fact, our recent research identified that, among the people that manage spare parts inventory, very little is known about best practices – that is, what top performers do better than others, what to focus