Understanding spare parts inventory health is both simple and complex.

Understanding spare parts inventory health is both simple and complex.

Simple because the actions required to establish an effective spare parts management system are well documented (just read one of my books!).

Complex because there are many ‘moving parts’ (pardon the pun) and that means many things can go wrong that can (and do) have a major impact on your results.

By failing to understand this, companies will experience one (or more) of the 9 symptoms of poor spare parts inventory health:

- Excess spare parts inventory

- Difficulty in determining what to stock & how many

- Stock that just doesn’t move

- High levels of obsolete spare parts

- Downtime and lost production due to stock outs

- Low levels of inventory accuracy

- Difficulty identifying critical spares

- Trouble controlling repairable spares

- Uncertainty about end-of-life spare parts management

Individually, experiencing any one of these symptoms will cost you money. In combination they result in companies wasting a fortune in spare parts inventory costs.

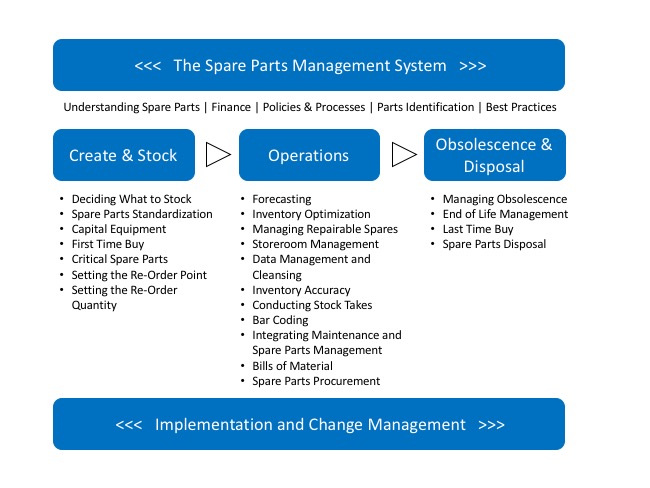

To ensure that your financial and operation outcomes are the best that they can be you need to be aware of the issues that arise during each phase of the spare parts management life cycle shown below.

By using this diagram as a kind of ‘road map’ you can be more certain that you consider all the factors that affect your spare parts inventory health.

The Systems and Phases Affecting Your Spare Parts Inventory Health

The Spare Parts Management System

The spare parts management system guides the activity and decision making throughout the life cycle of the spare parts held in inventory. It is therefore vital that the people engaged in establishing your system understand spare parts management and the life cycle decisions, not just supply chain or generic inventory management.

The Create and Stock Phase

The two most important decisions in spare parts inventory management are whether or not to stock an item and how many to stock. It is these decisions that determine if you have the stock that you need and how much money you spend on your inventory. It is in this phase of the life cycle that a company has the greatest influence on its spare parts inventory and getting the answers to these questions ‘wrong’ makes everything else that follows that much harder.

The Operations Phase

Following the create and stock phase, the longest part of the spare parts life cycle is the operations phase. The decision to create an item and stock it in your inventory may be made in minutes, but the item can then be part of your inventory for years or even decades. During this time, for most spare parts, the item (and the storeroom team) will be involved in a wide range of activities that impact your ongoing and future results

The Obsolescence and Disposal Phase

No matter how an item was first created or how long it is part of an inventory, it is almost inevitable that at some point it will become obsolete. It will therefore require removal and disposal. Companies must address this final phase of the life cycle through end-of-life management, conscious consideration of the last-time buy, the management of obsolescence, and understanding the options for spare parts disposal.

Why You Need a Roadmap

When you have no road map to help you work through all of this your only choice is to work it out as you go along. Unfortunately, that approach is the default position for most companies and it costs them a fortune in excess inventory, poor availability, and extended downtime.

By understanding the complexity of spare parts inventory management, and the interaction of all the ‘moving parts’ you can recognize and avoid the 9 symptoms of poor spare parts inventory health. This will then free you of the constraints that are holding you back and help you to achieve your spare parts inventory goals.

If you have Pro Level access at SparePartsKnowHow.com you can access training and information to guide you through each stage of the spare parts inventory life cycle, including best practices, policy templates, and ‘how to’ videos. Click here to visit the Online Resource Library Home Page

Author: Phillip Slater