“Goals are good for setting a direction, but systems are best for making progress.”

In the world of spare parts inventory management, the difference between success and failure often comes down to more than just good intentions or end-state goals. It depends on the quality and consistency of the systems that support operations day in and day out.

In the world of spare parts inventory management, the difference between success and failure often comes down to more than just good intentions or end-state goals. It depends on the quality and consistency of the systems that support operations day in and day out.

Most organizations set goals like:

- Reduce inventory costs by 10%

- Achieve 98% fill rate

- Minimize stockouts to fewer than 3 per month

These are all worthy objectives. But problems arise when the focus remains on the result without designing the systems needed to achieve and sustain it.

A goal might set the direction, but without a well-defined system, you’re relying on hope, not strategy.

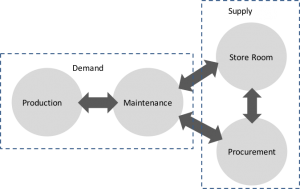

Think of systems as the daily habits of your organization. In spare parts management, these systems include:

- Data accuracy: Reliable master data for parts, suppliers, and usage history

- Automated reordering rules: Configured for lead time, criticality, and variability

- Maintenance planning: Integrated with inventory systems to forecast part usage

- Cycle counting programs: For continuous accuracy checks

- Inventory Reviews: For relevance of max-mins, criticality, and obsolete items

- Systems Prevent Firefighting

- Systems Work When People Change

- Systems Drive Compounding Improvements

Instead of reacting to shortages or excess, a good system anticipates and manages risk. Forecasts, safety stocks, and reorder points ensure you’re always a step ahead.

Employees come and go. If your inventory health depends on one person’s memory or initiative, you’re exposed. A system embeds knowledge into processes.

Small changes to inventory turns, lead times, or order frequency can add up to significant long-term benefits—if consistently applied.

Start by auditing your current systems:

- How long since your last max-min review

- Is your inventory data clean and standardized?

- Are parts classified by criticality and purpose?

- Do reorder policies reflect real lead times and risk tolerance?

- Is there a standardized approach to deciding holding levels?

Then, build or improve:

- Planning systems that span internal silos, using real data

- Review systems for continuous improvement

- Measurement sand reporting systems aligned to behaviors, not just outcomes

- Stock decision systems to eliminate emotional decision making

James Clear’s wisdom applies directly to spare parts inventory: goals are good for vision, but systems win the day. The companies that thrive aren’t just the ones with the biggest targets. They’re the ones with the best systems.

If you found this valuable and you want to dive deeper into this topic, you can review your training options here.

Posted by Phillip Slater