Understanding safety stock is one of the most important attributes of high performing spare parts inventory management.

Understanding safety stock is one of the most important attributes of high performing spare parts inventory management.

Companies that do not understand this will almost invariably over stock their inventory AND experience excessive stock outs. Here is the definition of safety stock.

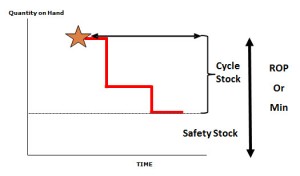

Safety Stock: Items held as an allowance for mismatches between demand and supply during the lead time to restock. The safety stock is used as a buffer between unexpected delays in the lead time delivery of stock or unexpected additional demand during the lead time of delivery of stock.

Sometimes users of SAP apply a definition of safety stock that adds the reorder quantity to the reorder point plus allowance for any stock on order or reserved for future use. In my opinion this definition is misleading as it effectively includes all stock as safety stock.

Safety stock is the main mechanism for risk management with spare parts inventory so using the SAP definition of safety stock without understanding the elements that make up that definition will lead to companies holding far more inventory than is necessary for their situation.

Source: Smart Inventory Solutions 2nd Ed. Phillip Slater. Published by Industrial Press

http://www.amazon.com/Smart-Inventory-Solutions-Management-Engineering/dp/0831134011

For information on our Pro Level membership please visit our Pro Level page.

Posted by: Phillip Slater