Translate the Supply Chain General to the Smart Spare Parts Management Specific

Recently I attended the Smart Supply Chain and Logistics Conference in Melbourne Australia. This is usually referred to as the Smart Conference.

Now you may be asking yourself, ‘what has a conference dealing with distribution centers, warehouse automation, and trucks, have to do with spare parts management’? As it turns out, plenty! You just need to translate some of the discussions from the general supply chain to the specifics of spare parts management.

The conference had a very full complement of speakers across five streams, so as with most conferences, you do need to be selective about the use of your time by preparing in advance (see my article titled, How To Get The Most From Attending a Conference’).

At the Smart Conference there were three discussions that really caught my attention and that were applicable to spare parts management.

The Smart Spare Parts Management Competitive Weapon

The first was the opening keynote presentation ‘The Supply Chain as a Competitive Weapon’, delivered by Dr. Steven Melnyk, Professor of Operations and Supply Chain Management at Michigan State University.

The first was the opening keynote presentation ‘The Supply Chain as a Competitive Weapon’, delivered by Dr. Steven Melnyk, Professor of Operations and Supply Chain Management at Michigan State University.

In this presentation Dr. Melnyk spoke about the role of the supply chain in helping businesses realize their full potential. While the topic really was directed at products that a company makes and sells, the key concepts were easily translatable to a company’s own supply of spare parts that are used to support its own operational functions. Think of this as the Spare Parts Management Competitive Weapon.

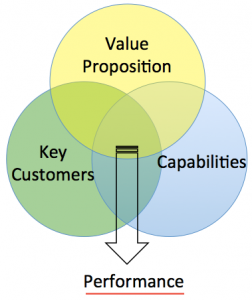

The central concept related to the ‘all important business model’ and focused on the intersection between the value proposition, key customers, and capabilities (see accompanying figure).

As you can see from the accompanying figure, the intersection of these issues is where you need to be to deliver real performance. I wonder how many spare parts managers working in asset-intensive companies have considered these three issues in relation to their department or function.

Perhaps all managers of the spare parts function need to be able answer the following set of questions:

- What is the value proposition for the spare parts storeroom?

- Do the storeroom personnel know and understand that value proposition?

- Has that been communicated to the rest of the company?

- Have the key customers been identified? These might be people, departments or specific machines.

- How do they relate to the value proposition?

- What capabilities are required to deliver on the value proposition?

- Are skills audits utilized to ensure that the capabilities are identified?

- Is there a plan to train staff in order to ensure the right capabilities are in place? Too often I see companies that look upon storeroom management as being the job that you give to people who can’t do much else. Which of course is not correct and is totally unfair!

Working through these questions and addressing their implications takes most companies down a path that leads to change and this means developing the skills to be able to manage that metamorphosis.

Changing Spare Parts Management Technology

The second speaker that caught my eye was also proposing change in spare parts management but a change in technology as well as process.

This speaker explored the use of industrial vending machines and how they can be used for the controlled provision of parts, tools and personal protective equipment.

Based on the case studies shown, it seems like this technology has moved a long way from the idea of a ‘coke machine’ or the delivery of coffee or chocolate bars. Modern industrial vending machines connect with your ERP or spare parts management software, they alert the vendor or your own storeroom of low parts levels, they identify users of tools, and they are shown to reduce the actual usage of consumables and PPE. This approach to automated and in-situ parts issuance saves money and produces a genuine return on investment.

Adopting the Latest Consumer Trends

Technology change was also the theme of the last speaker I saw at the conference.

This closing keynote presentation focused on the future of e-commerce and the latest trends. While the focus was on what’s called omni-channel retailing, the reality is that the concepts, technology and challenges from the retail sector will no doubt soon become evident in spare parts management at an operational level.

The growing expectation in retail is that we can get anything, anywhere, at any time, and get it now at the lowest possible price! Managing this expectation is and will continue to be no easy task.

Of course some will argue that this is already the expectation of the maintenance customer and so spare parts management is ahead of the trend.

However, procurement processes that lock in contracts and pricing mean that what we don’t yet see in spare parts management is the same widespread application of technology to help manage spare parts procurement and provision. Imagine being able to look up prices online and then instantly negotiate a better price with the vendor.

This is common-place in the retail world. Ultimately the lesson here is the need to be nimble in the management of parts, the supply chain, and technology in order to meet value proposition for the key customers. Which brings us neatly back to Dr Melnyk’s view on the need for capability development.

Spare Parts Management is Different

Regular readers will know that I advocate a position that spare parts management is different to the management of other inventory types. However, this doesn’t mean that we can’t find inspiration and insight from attending conferences addressing a more generic view of the world. We just need to be able to interpret that to the spare parts management dynamic.

Phillip Slater attended the Smart Conference as a guest of the conference organizers.

For information on our Pro Level membership please visit our Pro Level page.

Posted by: Phillip Slater