Stock turn is one of, if not the, most important metrics that you can use to measure the effectiveness of your spare parts inventory management. However, like all metrics you do need to calculate it and use it in the right way. One of the most common issues with stock

Definition of Just In Time (JIT)

Just In Time (JIT) is perhaps the most often quoted, and yet misunderstood, term in management. JIT, developed as one pillar in the Toyota Production System (the other being autonomation), is a production management method that aims to eliminate waste and improve product flow on a production line. This is

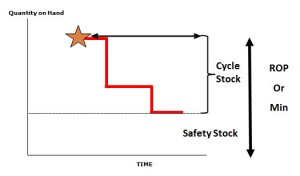

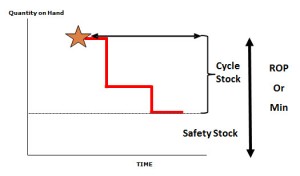

Reorder Point Definition – What You Need to Know

Understanding the Reorder Point Definition is Vital Understanding the reorder point definition is a vital element of understanding and being able to effectively execute spare parts management. With a clear understanding of the reorder point definition companies can avoid two key problems: The problem of overstocking due to over-estimating the reorder

Economic Order Quantity Definition

EOQ is often misunderstood to be the purchase quantity that provides the lowest purchase cost per unit. For example, when buying in bulk, and as a result many organizations overstock their inventory believing that they are doing the right thing. However, a better definition of Economic Order Quantity takes into account

ABC Analysis Definition

An ABC analysis is an analytical approach to inventory management. The analysis aims to divide the inventory items into categories and then tries to identify the items that are most important. Typically A is more important than B and B is more important than C and so on. The

Safety Stock Definition

Understanding safety stock is one of the most important attributes of high performing spare parts inventory management. Companies that do not understand this will almost invariably over stock their inventory AND experience excessive stock outs. Here is the definition of safety stock. Safety Stock: Items held as an allowance for

MRO Definition (Plus Materials, and Spare Parts)

Here is a useful and practical MRO definition that identifies MRO separately from materials and spare parts. Often people refer in books, magazines, blogs, presentations and so on to MRO, materials, and spare parts; but what do these individual terms really mean? And does it really matter? This is the

Who is Phillip Slater?

That’s a fair question. After all if you are going to join SparePartsKnowHow.com for online training and information then you want to know who Phillip Slater is and why this website will work for you. Let’s face it, there is plenty of material on inventory management out there on the

MRP Definition

Is the technique known as Materials Resource Planning misunderstood? Well, in the world of materials and spare parts management for maintenance support I certainly think that it is. Here is our MRP definition: Materials Resource Planning (MRP) is a management technique that is used to

Supply Chain Management Definition

APICS, The Association for Operations Management uses the following Supply Chain Management definition: ‘design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand and measuring performance globally.’ That’s quite a mouthful