Why is it, that despite the best efforts of management teams, the vast majority of spare parts inventories remain bloated with excess, surplus and obsolete items, while also not providing the level of service expected by the users?

Why is it, that despite the best efforts of management teams, the vast majority of spare parts inventories remain bloated with excess, surplus and obsolete items, while also not providing the level of service expected by the users?

How can companies, achieve the right balance between inventory cost and parts availability, knowing that they have done all that they can do?

The answer lies in the concept of True Optimization™.

Optimization (of anything) is a problem-solving process or methodology that aims to make something as functional and effective as possible*.

Common examples of optimization include:

- in travel, deciding the fastest route to get somewhere (optimizing the use of available time)

- in manufacturing, deciding the most appropriate production run times based on change over requirements and demand (optimizing production capacity)

- in design, deciding the appropriate shape and size of a product (optimizing material cost)

- And of course, with spare parts deciding how many of a specific spare part to hold in inventory (optimizing capital spend)

The problem is that what is mostly described simply as ‘optimization’ is not really optimization at all.

Or at least optimization of the factors that lead to holding the most appropriate levels of spare parts inventory.

Simple optimization is about optimizing within operational constraints, and the problem is that mostly the constraints go unchallenged.

This approach then limits the possible outcomes of the solution.

So, ironically, simple optimization doesn’t (in fact can’t) result in an optimal solution!

These constraints aren’t limited to things like time and quantity.

They can be any assumptions that limit the possible outcome of the optimization activity.

They can be self-imposed (i.e., assumed) or systemic (e.g., supplier minimum order size).

In the case of spare parts inventory, this includes assuming that:

- The future will look like the past (in terms of parts demand)

- The lead time for delivery is already optimal (or at least can’t be varied)

- Team behaviors such as hoarding cannot be changed (which impacts demand variability)

- Repairable parts will be managed appropriately (it’s usually not)

- End-of-life disposal will happen quickly and efficiently (rarely, if ever)

- Purchase pricing is minimized (often this is achieved by purchasing inferior parts)

- The minimum order size can’t be varied (not necessarily true)

- Existing policies and processes are appropriate and actually followed (almost never)

- Master data is up to date (stop laughing!)

- Decision workflow is appropriate and not by-passed (we know that ‘work arounds’ are common)

- Team members are trained to act in a timely manner and make appropriate decisions (training?)

- Parts in stock will be maintained and kept in a ‘fit for service’ condition (sure, whatever you say)

This list is not exhaustive but we think it illustrates why what most people think of as inventory optimization, isn’t really optimization at all.

True Optimization™ requires recognition of the constraints, both self-imposed and systemic, and then challenging these through a process of continuous review and improvement.

Breakthrough improvements can only be achieved by challenging the constraints in the original thinking.

High levels of materials and spares inventory are a symptom of the broader issues with the way the inventory is controlled, supplied, accessed, purchased, and managed.

In the real world, inventory levels are determined by a combination of supply chain management, internal policies and processes, and people’s behavior and training.

These issues involve a wide range of personnel who come from engineering, maintenance, stores, inventory management, procurement, and even finance.

Achieving True Optimization™ and lasting results requires an understanding of all the behaviours, context, and process factors that influence the inventory.

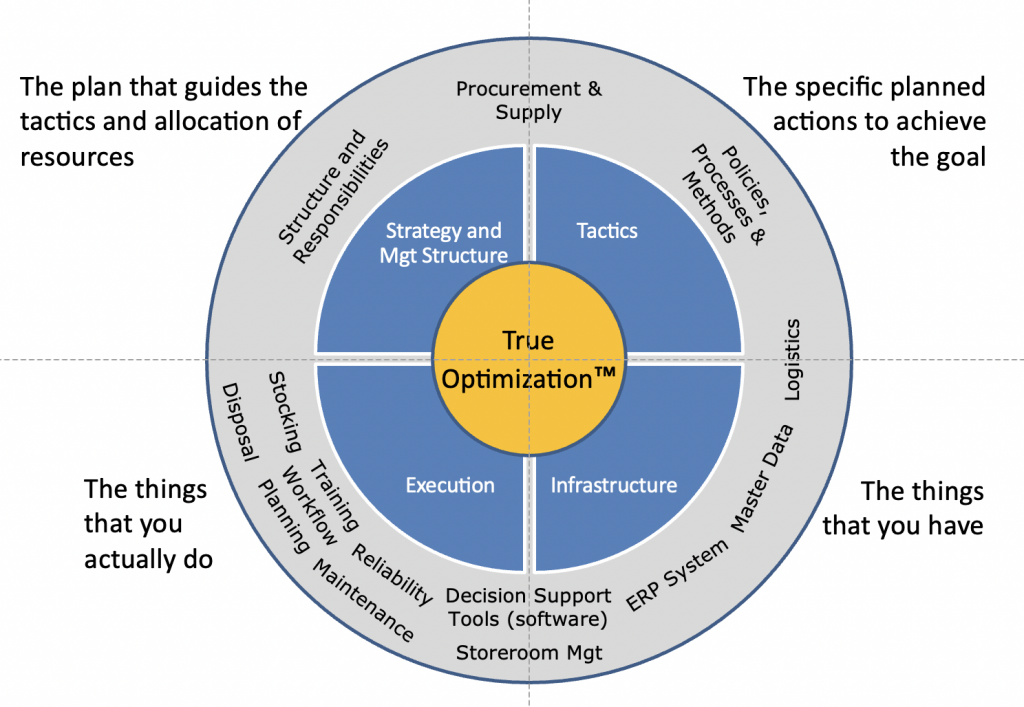

The range of issues to consider is shown in Figure 1.

First, aiming for True Optimization™ doesn’t mean that you shouldn’t use ‘optimization software’ as a decision support tool.

When faced with thousands (or tens of thousands) of items to review the use of software that can complete that review in a short period with the click of a mouse is an obvious choice.

However, your endeavour should not end there.

Achieving True Optimization™ requires the examination of the range of constraints that could limit the achievement of the optimization goal.

With reference to Figure 1, it is easy to see that there are many issues that might limit the ultimate effectiveness of the approach and that should be addressed.

The following is a selected sample.

- Is the management structure and allocated responsibilities aligned with the overall goal or does it interfere with the achievement of the goal?

- Does that structure result in the most appropriate allocation of resources to achieve the goal?

- Could alternative procurement and supply arrangements enable better pricing, better quantities or a more efficient process?

- Is the master data management suitable for the purposes, ensuring few or no duplicates, for example?

- Are the policies in place appropriate for the goal, and does the organization actually follow them?

- Is obsolescence and disposal handled in a timely and effective manner that maximizes the return on these outdated assets?

- Is the team sufficiently trained to know what’s important, what’s effective, and what makes a difference?

The final question in the above list really speaks to whether the team knows where to prioritise when going beyond the application of software.

Every company will be in a different position and so this prioritization is not trivial.

The extent to which aiming for True Optimization™ will benefit your company really depends on where you stand right now.

The extent to which aiming for True Optimization™ will benefit your company really depends on where you stand right now.

Some companies might be satisfied with the inventory results they achieve, while others will know that they need help.

For all companies, however, the question isn’t what are the inventory results today but what could they be if the right approach is applied?

For most companies their spare parts inventory is far from optimal.

Even companies that use well known and sophisticated software have glaring issues and bloated inventories because their management systems allow this to happen.

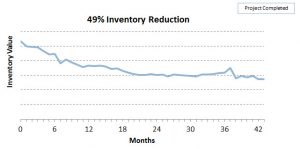

In our experience, companies that take the True Optimization™ path can save as much as 50% in their inventory spend while also improving parts availability.

The average is 37%. That is quite a payoff!

Now you might be thinking that these companies must have been pretty bad to start with but they didn’t think so.

And in our experience, this is common. The reality is that they didn’t know what they didn’t know.

However, by striving for True Optimization™ they were able to identify and implement changes that made a very material difference to their bottom line.

Reportedly, it was Albert Einstein that said, ‘you cannot solve today’s problems with the same thinking that created them’. This is taken to mean that if we understood the nuances and options then we would not be in the position we find ourselves.

Put a different way, it is hard to get lost when you know the path.

It is precisely because the issues are many and the nuances subtle that here at SparePartsKnowHow.com we have developed as a platform to access a wide range of resources relating to spare parts inventory management and optimization.

Author: Phillip Slater